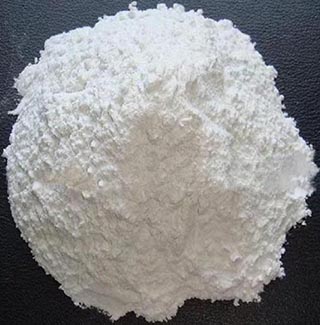

Calcined Cristobalite Powder (GORESIL)

GORESIL (Calcined Cristobalite Powder) is a high-temperature polymorph of silicon dioxide (SiO₂), produced by converting selected high-purity quartz in a rotary kiln at temperatures above 1500°C under catalytic assistance. The material features stable tetragonal crystal structure, excellent weather resistance, and strong thermal shock resistance.

Main Applications

GORESIL is widely used in enamel frit and glaze formulations, refractory raw materials, ceramic and pottery production, industrial grinding and polishing, as well as glass and coating industries.

Technical Specifications

| Item | Specification |

|---|---|

| SiO₂ | 99.5% min |

| Whiteness | 95–98% |

| Crystal Phase | Tetragonal (Cristobalite) |

| Hardness (Mohs) | ~6.5 |

| Density | 2.2–2.3 g/cm³ |

Physical Properties

Appearance: Pure white fine powder

Solubility: Insoluble in water

Weather Resistance: Excellent

Thermal Shock Resistance: Good

Available Mesh Sizes

300 Mesh · 400 Mesh · 600 Mesh · 800 Mesh · 1250 Mesh · 2000 Mesh · 5000 Mesh · 8000 Mesh

Packaging & Storage

Packaging: 25 kg bags or 1 MT jumbo bags.

Storage: Store in a cool, dry place. Avoid moisture and contamination.

Shelf Life: Unlimited under proper storage conditions.

GORESIL Functions in Enamel Glaze

Acts as a refractory raw material, widens firing temperature range, prevents over-firing, improves glaze permeability and breathability, enhances structural stability during multiple firings, and reduces crazing and fish-scale defects.